Das Stammhaus der Firma Knapheide in Beckum, 1967 von Werner

Knapheide gegründet, ist das Engineering-, Vertriebs-, Verwaltungs- und

Fertigungszentrum und somit die Schaltzentrale der Gruppe.

Von hier aus werden die Aufgaben allerdeutschen Werke koordiniert.

Hochqualifizierte Fachingenieure entwickeln individuelle und innovative

Hydraulik-Lösungen für moderne Automationsansprüche. Per Computersimulation in

3D-CAD-Systemen können Ingenieure und Kunden noch während des

Entwicklungsprozesses die neuen Lösungsvorschläge erleben und bewerten.

Bei Knapheide wird seit jeher nach der Prämisse gearbeitet: „Nur wer die

wichtigsten Dinge selbst macht, hat ständig Einfluss auf Qualität und

Weiterentwicklung seiner Produkte.“

Alle Komponenten stammen aus eigener, nach DIN ISO 9001 zertifizierten,

Produktion und durchlaufen eine strenge Qualitätskontrolle.

So zeigt das Unternehmen Flagge für den Standort Deutschland und für beste

Fertigungsqualität.

Das Ergebnis dieser kompromisslosen Philosophie: besonders robuste, langlebige

Hydraulik-Systeme, die auch unter extremen Bedingungen zuverlässig und präzise

arbeiten. Die Knapheide-Gruppe hat alle Kompetenzen im Bereich ausgereifter

Hydraulik-Systeme.

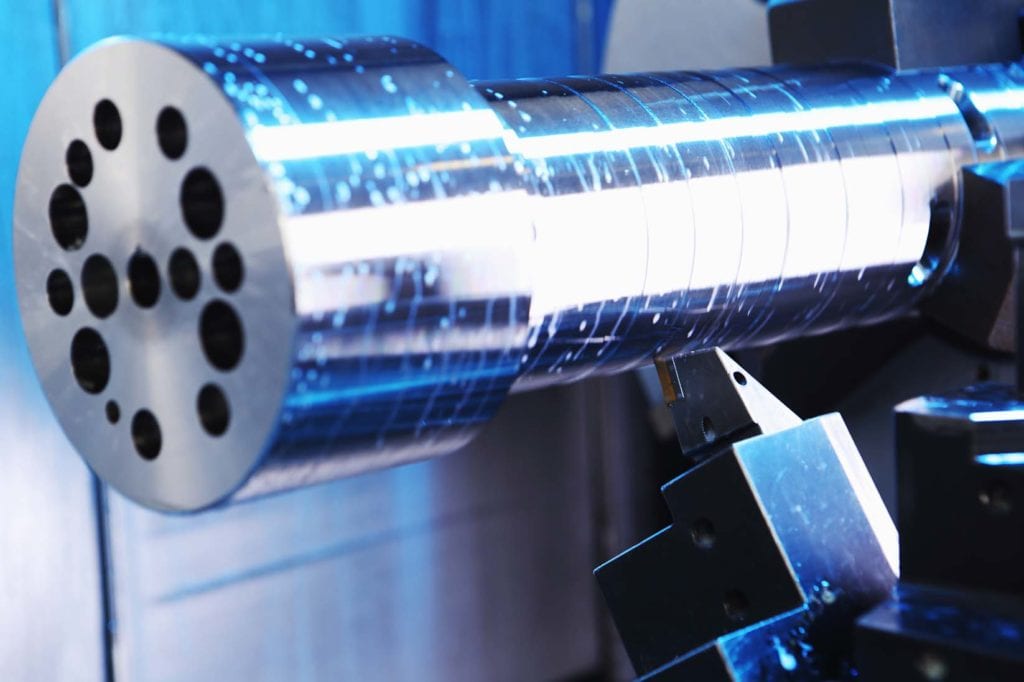

39 fully automatic six- and eight-spindle automatic lathes alone produce components especially for the high and ultra-high pressure range. Around 210,000 of these precision turned parts, such as hose and connection fittings, leave the factory every day.

Founded in 2013, the plant functions as a distribution and logistics centre for the entire Knapheide Group. With this newly created unit Knapheide is able to respond to customer requirements even faster and more flexibly. In the logistics centre the entire product portfolio can be accessed by means of innovative storage technology. Individual customer specifications and special delivery systems such as Kanban or the complete set composition can be implemented here. Buffer storage in the logistics centre also makes it possible to prepare our customers' production previews for defined periods of time and deliver them just in time.

We would be pleased to create individual logistics concepts in cooperation with you, which are exactly tailored to your needs.

The modern factory produces hydraulic hose lines in large series. Approx. 25,000 hose lines from DN 2 to DN 80 are assembled here every day, some of which are completely assembled according to the KANBAN system.